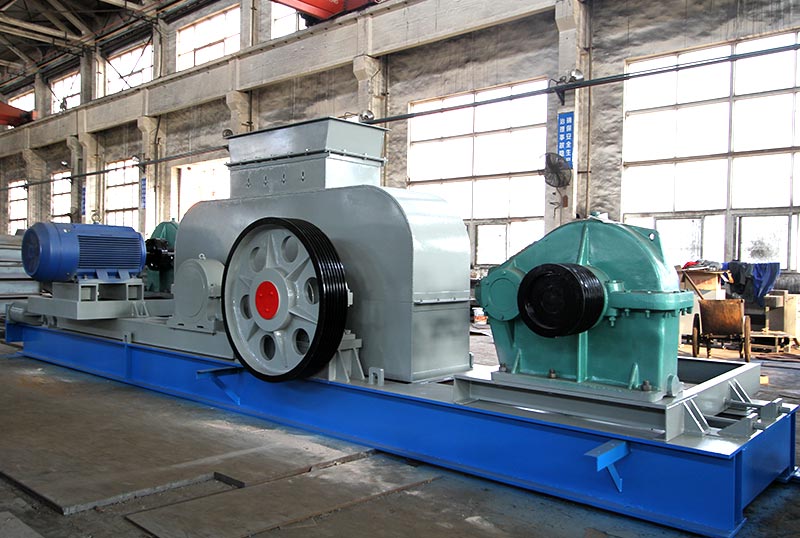

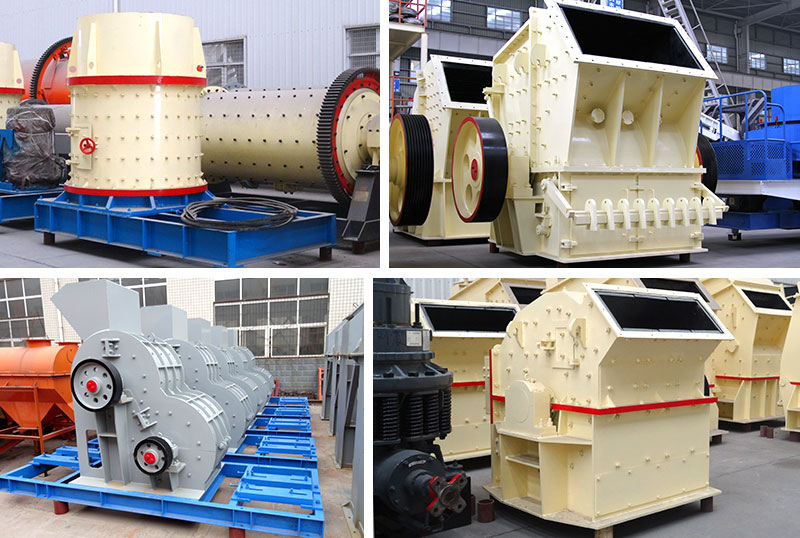

Crushers

Show our wide range of stone crushers including jaw crushers, impact crushers, cone crushers, hammer crushers, roller crushers and other types of stone crushers and mobile crushers consist of mobile jaw crusher, mobile impact crusher, mobile cone crusher.No matter what you are mining or processing, from rocks and metals to gold and oil shale, you'll need high-quality and high cost-performance stone crushing equipment to crush the raw materials into an optimal size. Welcome to contact us ---- we are here to help.

Screening

High quality is our unchangeable promise. As a leading China heavy machines manufacturer, we design and supply vibrating screens and rotary screens. The screening equipment enjoy the advantages of high specific feed rate, optimized drive concept, high availability and very robust design etc.

Washing

High quality is our unchangeable promise. As a leading China heavy machines manufacturer, we design and supply sand washer and spiral classifier for aggregate processing, mining, industrial minerals beneficiation processes, environmental mitigation and recycling separation processes.

Grind Mills

Show our wide selection of grinding mills including Dry Ball Mill,Raymond Mill and HGM Superfine Powder Grinding Mill and other related equipment consist of Bucket Elevator and Electric-magnetic Vibrating Feeder.No matter what you are mining or processing, from rocks and metals to gold and oil shale, you'll need heavy duty, industrial strength grinding equipment to grind down materials after the crushing process. Welcome to contact us ---- we are here to help.

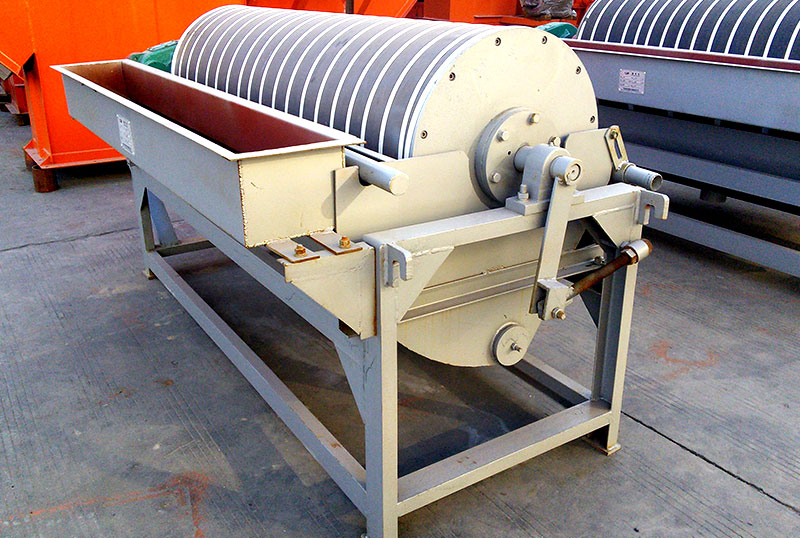

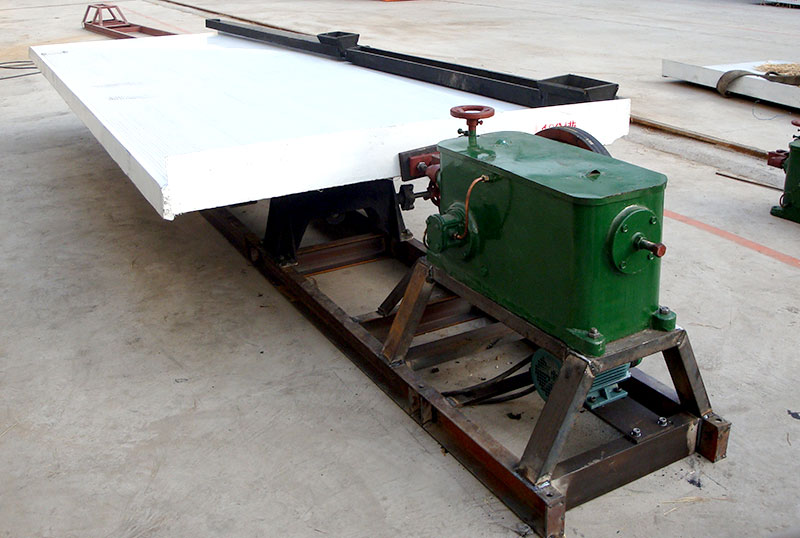

Mineral Processing Equipment

Fote Heavy Machinery Co, Ltd as a mining machine source supplier provided your mineral processing equipment and solutions for iron removing operation of coal, to separate nonferrous metal, ferrous metal, noble metal, nonmetallic mine, chemical material and recycle mine.

Cement Machines

As a leading China cement machines manufacturer, we design and supply cement equipment such as rotary kiln, cement mill and cooling machine, cement grinding mill for cement industry. We expertise in heavy fabrication with largest workshops in Luoyang in china with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Dryers

High quality is our unchangeable promise. Fote as a leading heavy machine manufacturer supplies Industrial Dryers such as Drum Dryer and Double Cylinder Dryer. These rotary dryers also were known as the equipment which is used in various sectors for drying and evaporating water. Fote drum dryers are sturdy in construction and are highly efficient. These rotary dryers meet the market demand in the drying plants for mining, chemical, and metallurgical industries.