The FTM hammer crushers are applied to the industries like railway, road, cement, building material, refractory, ceramic and chemical industry to carry out middle breaking and fine breaking to the raw materials.They mainly apply to crush limestone, tegular rock, dolomite bole, ground phosphate rock, gypsum, glass, manganese mine, refractory material, coke and others. The hammer crusher is also available to crush whitewashing stones, water stone, building sand, fine coke and with different fineness together with grate bar according to consumers' need.In addition, hammer crushers can not only be used for crushing production lines, sand production lines but also in the mineral processing line instead of cone crusher.

Hammer crusher's structure: crusher box, rotor, hammer head, counterattack plate, sieve and other components.The machine case is welded by medium carbon steel plate with many reinforcing steel bars. It is divided into two parts: case cover and base along rotor axis centerline. All the wall boards and impact plates in the case are made of 30# steel plate. Hammer head is forged with 55一60# type steel and the hardness can reach HRC500 or above after heating treatment.Generally, the crusher (size less than 600x400) is driven by the V-belt. Users also can adopt plate belt or direct link according to requirements.

1. The structure of the hammer crusher's case is easy to be disassembled.

2 .Using 30# steel as wallboard's texture is mainly in favor of extending the use life of the case.

3., Hammer head with new technology casting can attach wear-resistant and impact resistance effect.

4. The sealed hammer crusher body solves the crushing plant dust pollution and body leakage problem.

PCZ series of hammer crusher is mainly used in building materials industry, the construction of roads and railways, buildings, and other applications of stones. Especially it is suitable for crushing medium hard limestone, and the compressive strength is lower than 250MPa in crushing hard, brittle materials, such as limestone, dolomite, coal and calcium content higher than 40% the stone. The feeding size can up to 1000mm, and the discharging granularity can be adjusted according to customers' needs. PCZ heavy hammer crushers can turn two or three crushing circuits into one, simplify the crushing process, increase the utilization rate of the site, reduce 50% investment of the equipment, and the crusher's working efficiency is not reduced.

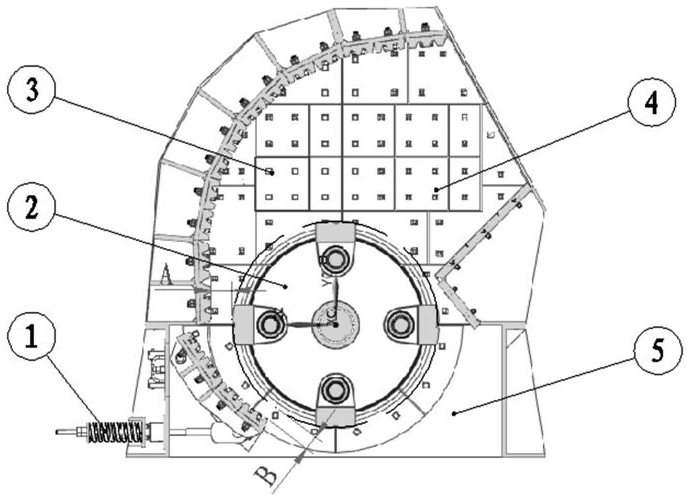

As is shown in the figure, the PCZ heavy hammer breaker mainly consists of 1- adjusting mechanism, 2-rotor, 3-after box of upper body, 4 - front box of upper body, 5- lower body

Easy to observe the machine situation and solve problem timely; On the third and fifth part, the observation hole is also open.

High-quality alloy wears resistant lining board and hammer can prolong service life and reduce the cost; In the back side, the flank of both sides and the feed ramp are equipped with high-strength and wear-resistant counter-liner. The high chromium alloy wear-resistant hammer rotor is equipped with advanced technology.

Uniform grain type; The different size of the material passes through the three counter zones, finished material flowing, the spring adjusting device can achieve the preset pressure self-adjustment.

Great crushing strength, high production efficiency; The inlet cavity of the main body of reasonable design, streamlined shell broken, completely matched with the rotor movement, material handling and high efficiency.

Convenient maintenance, reduce downtime; The hammer on the rotor can rotate 360 degrees along the axial direction, to prevent the motor blocking machine. At the same time, it equipped with hydraulic pump shaft., to facilitate the replacement of the hammer, hammer shaft.

PCZ (X) series of hammer crusher is installed in the chassis using a hammer and break the high-speed rotation of the kinetic energy of the material. When the material to be crushed by the feeding device, the material feeding port by breaking into the cavity, driven by the high-speed rotating rotor hammer first for the first blow to the bulk material, the material is broken or impact hammer thrown to the back plate; to obtain kinetic energy materials after speed crashed into the back plate or other material blocks and the crushing cavity collide and broken again; the material in the collision process gradually to the crushing chamber at the lower part of the activities of the counterattack plate movement, when the particle size is less than the gap between the hammer head and the back plate of the activities, from the crushing cavity in weight and other materials under the extrusion of material. After'iron hit stone',' stone hit stone',' stone hit iron' these crushing process in the crushing cavity, and finally by the discharge hopper.