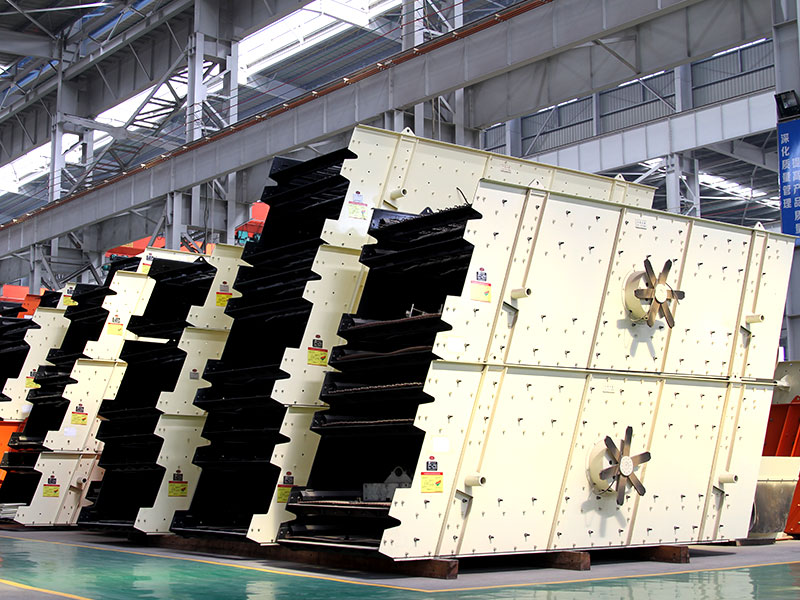

Vibrating screen belongs to the dry material sieving equipment and has a wide range of application, mainly used in quarry, mining and other assignments, sorting the crushed material according to material's granularity and having further processing according to their different uses. The product granularity can be adjusted independently.The new-type vibrating screen of Fote, using the circular vibration trajectory design, cylindrical eccentric shaft vibration exciter, the structure of adjusting amplitude by partial block and firm and durable rivet assembly, which greatly improves production efficiency and prolongs the service life.

Strong vibration and good sorting effect; Adopting eccentric block vibrating exciter to have high vibration frequency, multi-layer screen mesh and maintaining the maximum aperture ratio in the working process can realize fine screening.

Simple structure and stable operation; The vibrating screen is composed of the screen box, vibrating exciter, suspension device and motor, is convenient to install. Adopting flexible coupling, such as cross shaft , universal drive shaft or rubber coupling, to keep the machine running smoothly.

Less plugging and long service life; The screen is made of spring steels, which is strong and wear-resistant, plus intense resonance, so it's not easy to be clogged. The screen machine is divided into single layer, double layer, light-weight type and heavy-weight type. FTM provides customized services to help customer choose suitable machine according to the nature and purpose of the material and the production demand.

There aren't any differences in the external form between the circular vibrating screen and linear vibrating screen, and material's screening is achieved by screen surface's vibration to form motion trail. But as a result of different vibration track will directly affect the purpose of screening, which kind of equipment can meet the needs of industrial development more, and we make a contrast:

|

Circular vibrating screen |

Linear vibrating screen |

Vibrating track |

Parabolic and elliptical motion trail to make the material scatter sufficiently, meanwhile, the jigging action reduces the plugging phenomenon. |

The movement trajectory is linear, the material's amplitude is low, the time that material on the screen is short |

Application examples |

Main screening materials with heavy weight, large particles and high hardness. |

Main screening with fine particle, light weight and medium hardness |

Casting material |

The circular vibrating screen is usually made of a thicker plate. The material of the box body must be made of manganese steel, which is designed to resist the impact of the material in the screening process |

The material of linear vibrating screen is mainly made of light plate or stainless steel plate |

Through simple comparison and analysis, we can find the circular vibrating screen has more advantages than linear vibrating screen in weight, amplitude, efficiency, etc. It can replace linear vibrating screen in most areas, it has good screening effect, wide applicable materials, low maintenance cost and more strong and durable capacity. For different materials, our company can design and produce special circular vibrating screen for you.