Why Is the Product Quality of Cone Crusher Unqualified

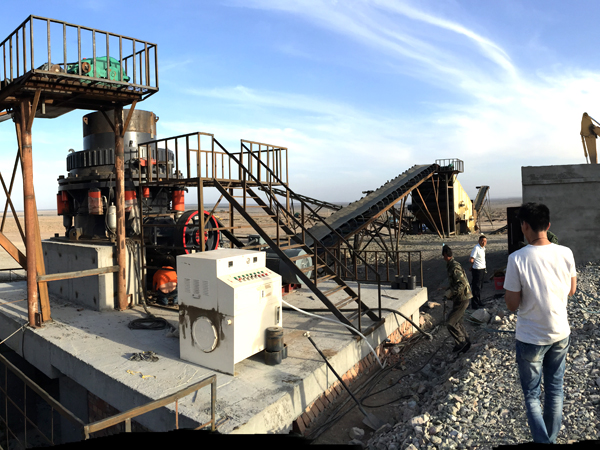

2017/11/30 adminCone crusher belongs to the secondary crushing equipment in stone production line. Generally, the finished products crushed by cone stone crusher can be used directly as the raw materials in the building and road construction. However, in the actual production, there are some factors causing the quality of finished product processed by cone crusher is too poor. It still needs to be handled at the third time, which greatly increases the user's production cost.

And what are the concrete reasons? After analyzing the aspects of the equipment itself, user's operation and some objective factors, FTM engineers sum up the following reasons.

1. The moving cone and fixed cone of cone crusher are broken.

If the moving cone and fixed cone of cone stone crusher are seriously broken, they will not exert the required crushing force. And the material will not be processed well so that the granularity of finished material is over-sized and its quality is unqualified.

2. The crushing chamber of cone crusher hasn't been designed reasonably.

The crushing chamber is the only crushing area of cone crusher. If its structure is not reasonable, it will do harm to the product quality. If the cavity height or depth of cone crusher doesn't meet the requirement, the material will be discharged from the cone crusher cavity without enough breaking times. As a result, the finished product quality is too terrible to meet the requirement.

3. Materials do not fit the bill of cone crusher.

Every equipment has the certain requirements for their feeding materials. The hardness and granularity of the materials should not exceed the maximum limit of cone crusher equipment. If they exceed the limit, cone crusher will not complete the crushing work on the materials wonderfully. Then, the finished product can't be up to the required demand of users.

4. The discharge port of cone crusher is adjusted too large.

In order to increase the cone stone crusher yield, some users try to widen the discharge port size of cone crusher even exceeding the maximum limit. Then the materials are discharged from the cone stone crusher without being crushed completely. Therefore the discharged materials are unqualified.

5. Unstable voltage

The stability of voltage will also affect the product quality of cone crusher. If sometimes the voltage is too low in the production process of cone crusher, it will not be able to drive the equipment's good crushing work. As a result, the processed materials size is uneven.

If these errors exist in your production, you should adjust them immediately to avoid the above situation. If the quality of your cone crusher is not qualified, it is recommended to replace the equipment timely and stop the non-effective production investment.

Fote Machinery has been engaged in mining equipment manufacturing for nearly 40 years. Whether considering the company scale, service quality, technical support or the equipment quality, it has been recognized by the majority of clients. If you are going to purchase the new cone crusher or other mining machinery, welcome consult us. FTM experts are always available online for replying you.