Why Are Cone Crushers More Expensive than Jaw Crushers

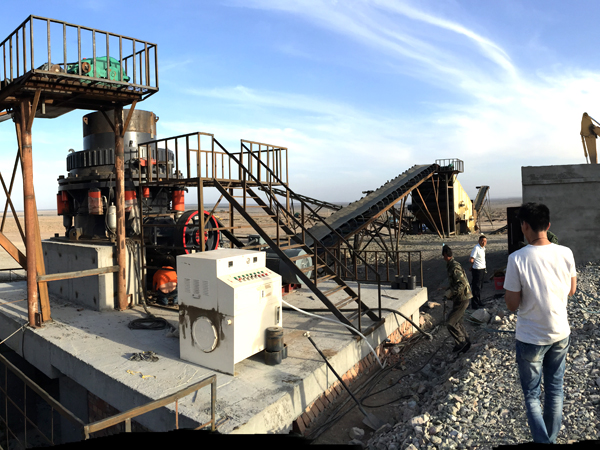

2017/11/24 adminCone crusher price mainly depends on its production cost. The reason why cone crusher is at the high price but can quickly occupy the market is that cone crushers have many advantages. First of all, cone crushers have large output and excellent grain shape, which can be said to be the main factors that cone crushers beat other stone crushers. Another factor is that cone crushers adopt the intelligent hydraulic system,which is convenient for users to implement the automatic operation.

Today we're going to compare the cone crushers and the jaw crushers, and analyze the reasons why cone crusher price is higher than jaw crusher price.

1. Stronger Production Capacity

The depth of cone crushers' crushing chamber is deeper than that of jaw crushers, so cone crushers have stronger production capacity than jaw crushers.As well as, the electricity consumption per unit of cone crushers is lower than that of jaw crushers.

Comparing one Symons crusher and one jaw crusher both in the same feeding port specification, the production capacity of the Symons crusher is twice as much as that of the jaw crusher. Meanwhile, when processing one-ton ore, the power consumption of the Symons crusher is 0.5 to 1.2 times lower than that of the jaw crusher.

2. More Stable

The crushing work of cone crushers is relatively more stable, and cone stone crusher vibration is relatively lighter than jaw crusher in the crushing process. And cone crushers don't need the bulky foundation and anchor bolts for installation, but jaw crushers need.

3. Direct Feeding of Raw Materials

Cone stone crusher cavity can be filled with the material during the production process.For large cone crushers, they allow the direct feeding of raw materials without the additional storage bin and feeder machine.However, jaw crushers are not suitable for that feeding way. They require the raw materials should be fed evenly. So it is necessary to set up one storage bin and one feeder machine for jaw crushers. When the rock particle size is larger than 400 mm, users need to configure a heavy-type vibration feeder to help the jaw crushers production.

4. Startup procedure of cone crushers is convenient.

But the start of jaw crushers needs to be completed with the aid of auxiliary devices. Although it is only a small start progress, it cannot be underestimated for energy saving and reducing consumption.

5.Much Fewer Sheet Product

The finished product that produced by cone crushers has much fewer sheet product than that produced by jaw crushers.

6.Less Dust and Lower Noise

Due to the closed structure of cone crushers, cone stone crusher generated less dust and lower noise compared with jaw crusher. Therefore, using the cone stone crusher can reduce pollution to the environment and avoid the noise damage to staff.

From here we see that because cone crushers have higher advantages than jaw crushers, so the cone crusher price is higher than the jaw crusher price. Although users need much one-time investment for buying cone crushers, the long-term production cost and follow-up investment will decrease. The overall investment of cone crushers is not necessarily high. What's more, users can get more benefits from cone crushers than from jaw crushers. For specific cone crusher price, please consult FTM sales engineer online for free.