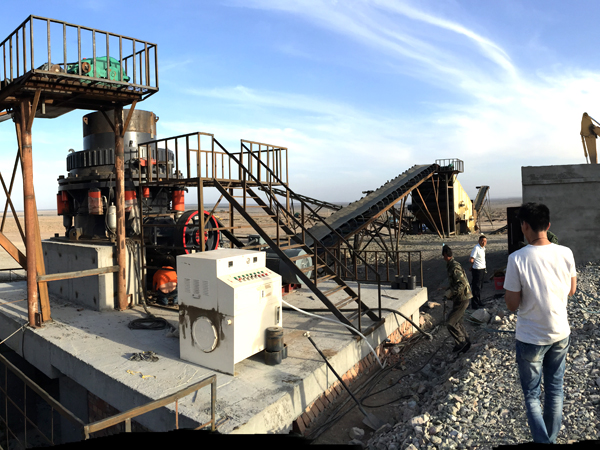

Contrastive Analysis of Cone Crushers and Jaw Crushers

2017/11/16 adminCone crushers and jaw crushers are two of the most popular crushing equipment in crusher industry. They are both applicable to crushing the raw materials in metallurgy, building, road building, chemical and silicate industry. In addition, cone crushers and jaw crushers both can form different production lines by matching with other equipment. However, there are also many differences between cone crushers and jaw crushers. Today we will make a systemic contrastive analysis on them in the following aspects.

Category description of cone crushers and jaw crushers

1. Cone crushers can be classified into six types according to its models. They are spring cone crusher, Symons cone crusher, GYS series hydraulic cone crusher, CS cone crusher (single cylinder hydraulic cone crusher), HP cone crusher ( HP series multi-cylinder hydraulic cone crusher) and mobile cone crusher.

2. Jaw crushers are divided into four types including CJ series jaw crusher, HD German jaw crusher, PE series jaw crusher, PEX series jaw crusher and mobile jaw crusher.

Structural description of cone crushers and jaw crushers

1. Here's an example of Symons cone crusher. Symons cone crusher parts are the mainframe, fixed cone liner, movable cone liner, spring device, bowl type bearing and transmission shaft, etc. The auxiliary parts of Symons cone crusher are the electrical system, oil lubricating system, and the hydraulic cleaning system for adjusting the discharging port.

2.Jaw crusher is composed of main frame, stationary jaw plate, movable jaw plate, movable jaw, eccentric shaft, toggle plate, adjustable toggle seat.

Operating principle of cone crushers and jaw crushers

1.Cone crusher operating principle can be briefly introduced like this: In the production of cone crusher, it does the rotary oscillation. When the movable cone of cone crusher rotates, it does the eccentric swinging, which drives the fixed cone liner and movable cone liner to extrude material.

2.In the operation of jaw crusher, the movable jaw drives the movable jaw plate and fixed jaw plate doing the reciprocating extrusion movement so as to complete the crushing process on materials.

In short, the cone crushers finish the crushing process by the rotary oscillation and its motion trail is circumferential; And the jaw crushers crush the material by doing the reciprocating swing and its movement trajectory is straight. Compared to the jaw crushers, the working process of the cone crushers is continuous. The force to the material in the crushing chamber is the resultant force of bending force, shearing force and friction force, so the material is more likely to be crushed in the cone crushers cavity.

Applicable materials of cone crushers and jaw crushers

1. Cone crushers are used for crushing medium-size stones and often used in the secondary crushing process. Cone crushers can crush materials within the range of 35 mm~300 mm granularity. They have a great advantage in crushing high-hardness minerals and rocks such as granite, marble, pebbles, dolomite, rhyolite and diabase.

2. Jaw crushers are mainly used for crushing the relatively larger sized material, the material granularity should be kept within the range of 125 mm~1500 mm. Jaw crushers are usually used in the primary crushing stage. They are suitable to crush various rock and ore materials with compressive strength not greater than 320Mpa.

Crushing capacity of cone crushers and jaw crushers

1. The design of cone crushers crushing cavity is diverse, so users can choose suitable cavity type according to their different needs. Cone crushers are mainly used for the medium and fine crushing operation. The cone crushers with standard cavity type are suitable for medium crushing operation, medium head cone crushers are appropriate for fine crushing production, and short head cone crushers are the same with the ultra-fine grinding. In addition, the production capacity of cone crusher is 12-2020 t/h.

2. Jaw crushers are mainly used for coarse and medium crushing operation. The throughput of jaw crusher is 5-1200 t/h.

Above content is a comparative analysis of cone crushers and jaw crushers on several aspects. Fote Machinery hopes it can help customers have the more detailed understanding of these two crushing equipment. If you have any other questions, please contact us online for free, FTM professional engineers are waiting to answer for you.online for free, FTM professional engineers are waiting to answer for you.